Ceramic Fiber Blanket

Ceramic Fiber Blanket

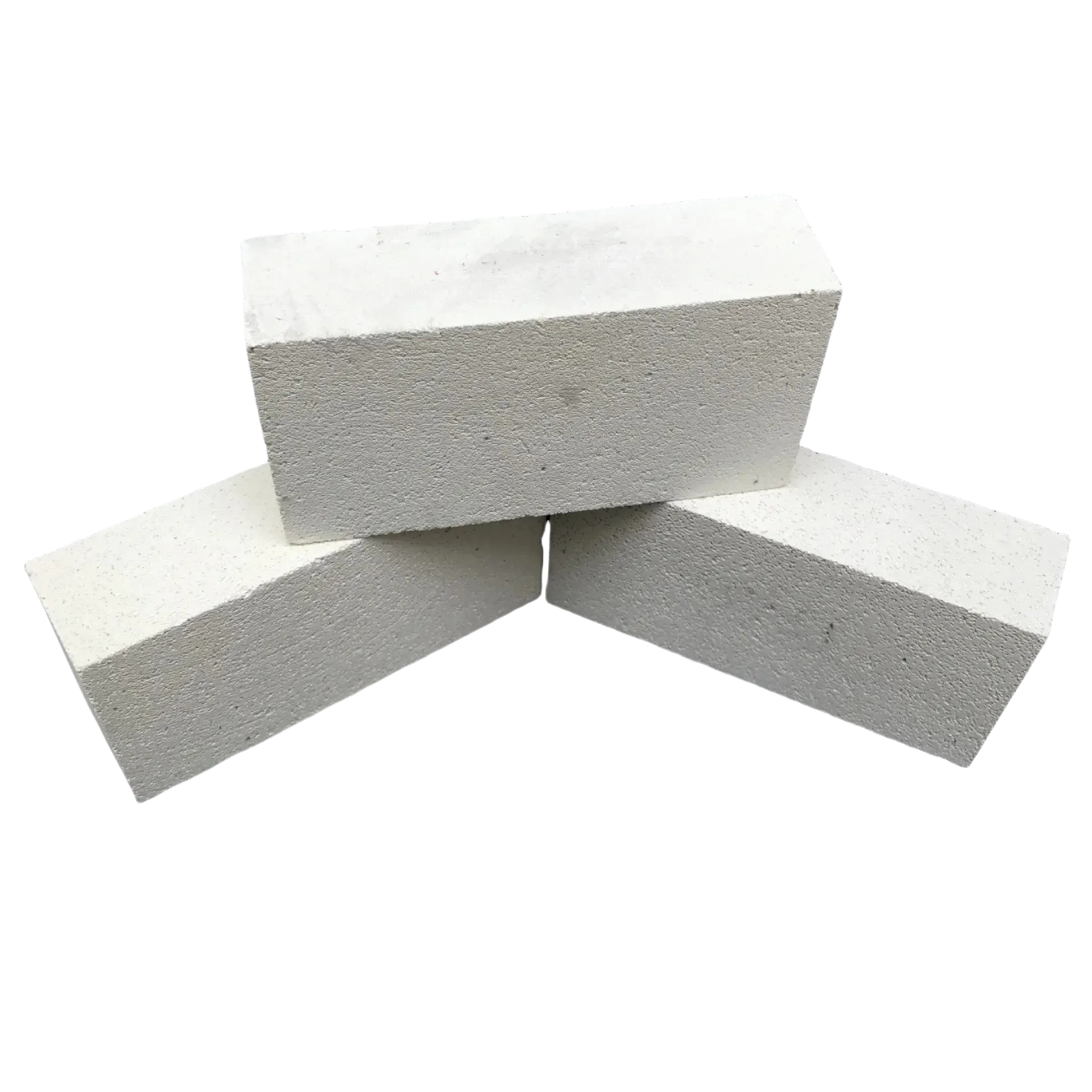

Ceramic fiber blanket , also known as aluminum silicate fiber blanket, is called ceramic fiber blanket because one of its main components is alumina, and alumina is the main component of porcelain. Ceramic fiber blanket integrates the advantages of fire resistance, heat preservation and heat insulation.

Ceramic fiber blanket is made by continuous production through a double-sided needling process, which does not contain any binder or other ingredients. Meanwhile, the enhanced needle punching process increases the degree of interweaving of fibers and the anti-delamination performance of the blanket. Therefore, this process of makes it have good tensile strength without affecting its flexibility.

Item | Specification | |||

STD | HP | HA | HZ | |

Al2O3 % | 44~46 | 47~49 | 52~55 | 39~41 |

Al2O3+SiO2 % | 98 | 99 | 99 | / |

Al2O3+SiO2+ZrO2 % | / | / | / | 99 |

ZrO2 % | / | / | / | 15~17 |

Fe2O3 % | 0.5 | 0.2 | 0.2 | 0.2 |

K2O+Na2O % | 0.2 | 0.2 | 0.2 | 0.2 |

Density, kg/m3 | 64~140 | 64~140 | 64~140 | 64~140 |

Permanent Linear Shrinkage, % After 24h | ≤-3 1050℃ | ≤-3 1100℃ | ≤-3 1100℃ | ≤-3 1300℃ |

Thermal Conductivity, W/(m·K) Density 128kg/m3 | 0.14 800℃ | 0.14 800℃ | 0.13 1000℃ | 0.14 1000℃ |

0.17 1050℃ | 0.18 1100℃ | 0.19 1200℃ | 0.21 1300℃ | |

Tensile Strength, MPa 128kg/m3 | 0.04 | 0.04 | 0.04 | 0.04 |

Max Working Temperature, ℃ | 1200 | 1260 | 1350 | 1400 |

Linings of industrial kilns

Insulation material for high temp tube

Fire proof

Materials for ceramic fiber module