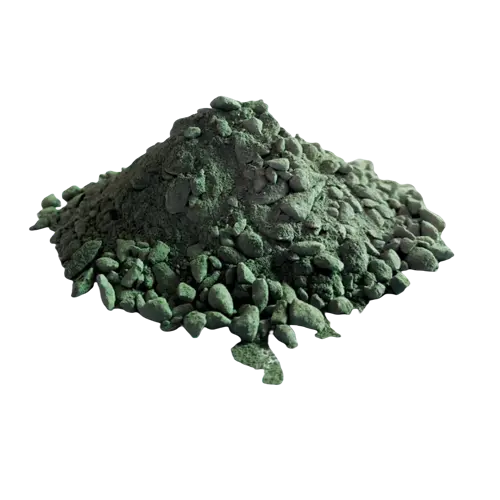

Chrome Corundum Castable

Chrome Corundum Castable

Chrome corundum castable as a kind of hot sales refractory castable for furnace application in refractory castable factory manufacturing with widely used in parts of carbon black reaction furnace, coal water slurry gasifier, incinerator, smelting furnace, steel making furnace, glass drawing furnace. Chrome corundum castable have good properties of high strength & stable thermal shock resistance & excellent performance. There are for sale cheap chrome corundum refractory castable in fire bricks company can provide chrome corundum refractory castable specification and category as well as competitive price & high grade quality refractory castable products, other specification according to customer requirements, welcome to contact us or email us for free quote or price list.

Item | CCC60 | CCC75 | CCC80 | CCC85 | CCC90 | |

Cr2O3(%) | ≥8 | ≥15 | ≥10 | ≥8 | ≥5 | |

AL2O3(%) | ≥60 | ≥75 | ≥80 | ≥85 | ≥90 | |

Fe2O3 (%) | ≤0.5 | ≤0.5 | ≤0.4 | ≤0.4 | ≤0.3 | |

Apparent porosity(%) | ≤18 | ≤18 | ≤18 | ≤18 | ≤18 | |

Bulk density | (g/cm³) | ≥2.8 | ≥3.2 | ≥3.0 | ≥2.9 | ≥3.1 |

Modulus of Rupture | (MPa) 110℃*24H | 8 | 9 | 10 | 10 | 11 |

(MPa) 1500℃*3H | 12 | 13 | 15 | 15 | 16 | |

Cold crushing strength | (MPa) 110℃*24H | ≥90 | ≥120 | ≥80 | ≥80 | ≥100 |

(MPa) 1500℃*3H | ≥150 | ≥155 | ≥155 | ≥160 | ≥165 | |

Refractoriness under load | (℃) 0.2MPa,0.6% | ≥1850 | ≥1900 | ≥1950 | ≥1970 | ≥1900 |

Working Temperature | (℃) 0.2MPa,0.6% | ≥1700 | ≥1730 | ≥1750 | ≥1770 | ≥1790 |

Particle size | mm. | 1~0, 3.0~1.0, 5.0~3.0, 200mesh, or customized. | ||||

Chrome Corundum Castable Definition

1.Chrome corundum refractory castable belongs to the series of composite corundum castables. Refractory chrome corundum castable is a new type of high-grade unshaped refractory material.Refractory castable can be used in 2000 degree high temperature kiln, the effect is obvious. Refractory chrome corundum castable is more than double the service life of traditional corundum castables.

2. The main components of chrome steel jade castables are aluminum oxide and chromium oxide. These two components can produce a corundum solid solution phase under high temperature. The solid solution phase is resistant to high temperature, erosion and wear. The wear resistant effect of chrome corundum castable is obvious.

3. Corundum castables are refractory castables prepared with corundum as aggregate and powder plus some binders. Refractory castable has higher mechanical strength and abrasion resistance than high alumina refractory castable and mullite refractory castable.

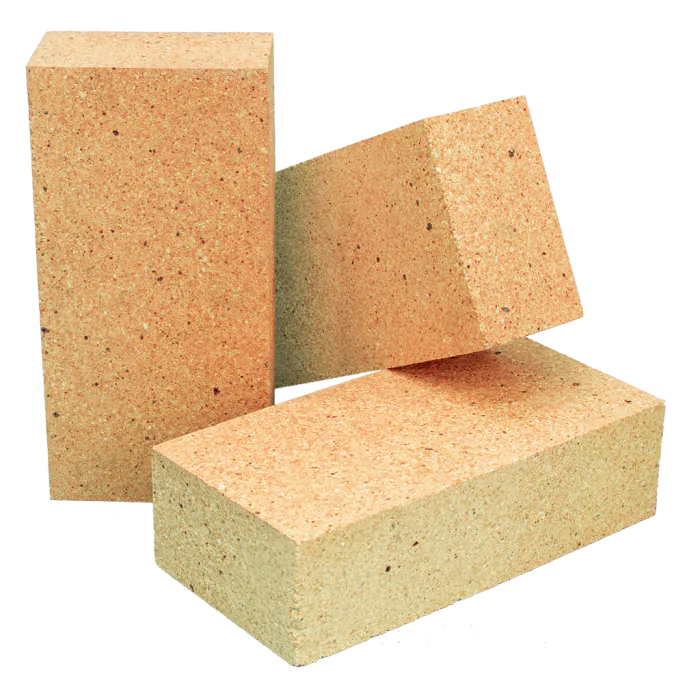

Chrome Corundum Castable Features

1. Refractory chrome corundum castable have high strength, stable thermal shock resistance and excellent performance.

2. Chrome corundum refractory castable has the characteristics of good volume stability, high strength, good wear resistance, corrosion resistance, erosion resistance, no cracking and no peeling.

3. Chrome corundum castable is easy to construct and can be poured on site or made into prefabricated parts.

4.Chrome corundum refractory castable has the least wear loss, high strength, arbitrary shape control, strong integrity, simple construction, good construction performance and high-strength wear-resistant refractory castables can be used by adding water and stirring on site.

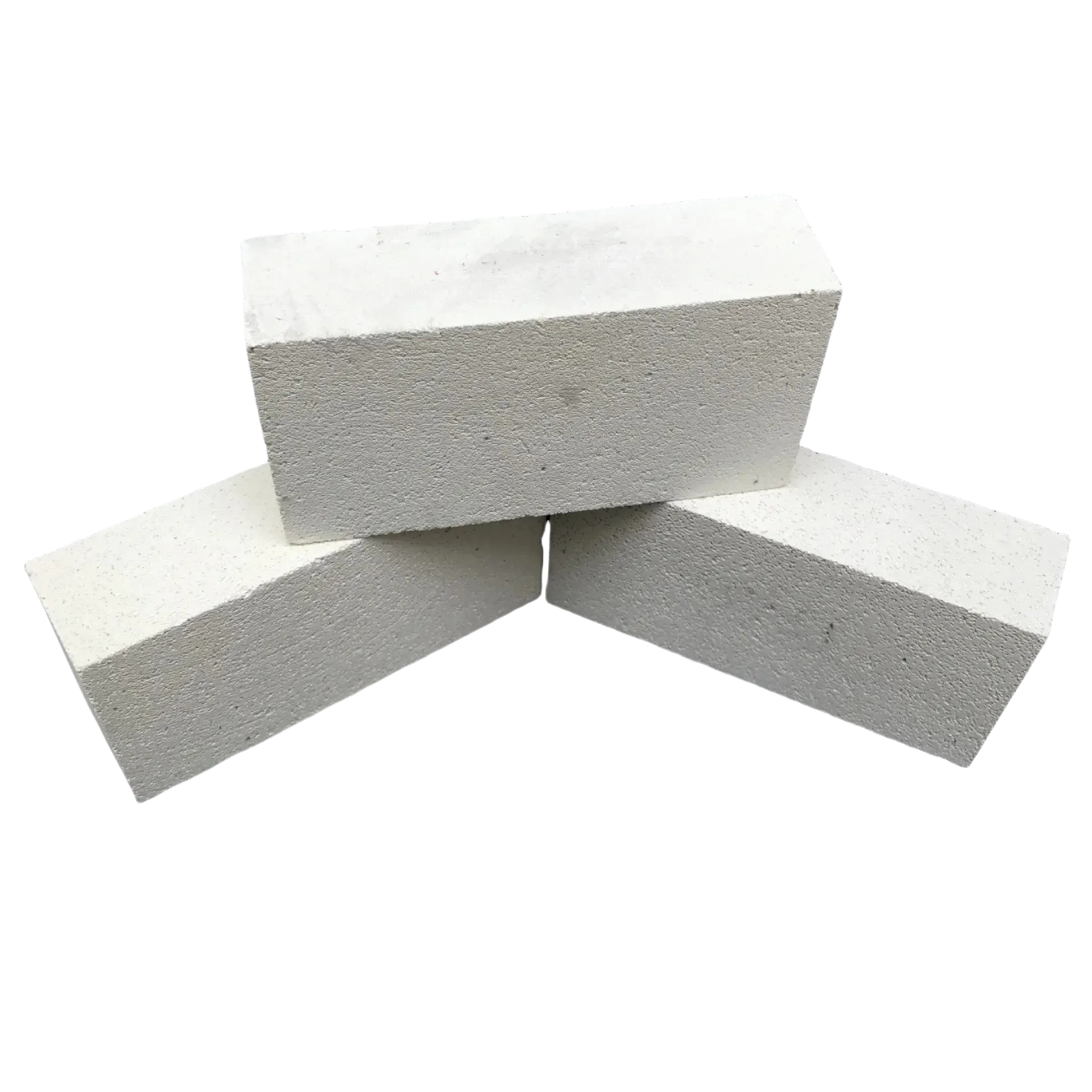

Chrome Corundum Castable Application

1.Refractory chrome corundum castables are used in various high temperature furnaces such as carbon black reactor, coal water slurry gasifier, incinerator, smelting furnace, steelmaking furnace, glass drawing furnace.

2.Chrome corundum refractory castables are used in carbon black reactor, iron alloy furnace, coal water slurry gasifier, the effect is very significant.

3.Refractory chrome corundum castable should be used as the lining material for various kiln such as boiler, blast furnace hot blast stove, heating furnace and ceramic kiln.

4.The melting furnace mainly uses ultra-high temperature chrome corundum brick or chrome corundum castable as the lining.

5.Refractory chrome corundum castable application in the carbon black plant carbon black reaction furnace, petrochemical kiln, heating furnace, garbage incinerator, non-ferrous metal smelting furnace and iron hook material.

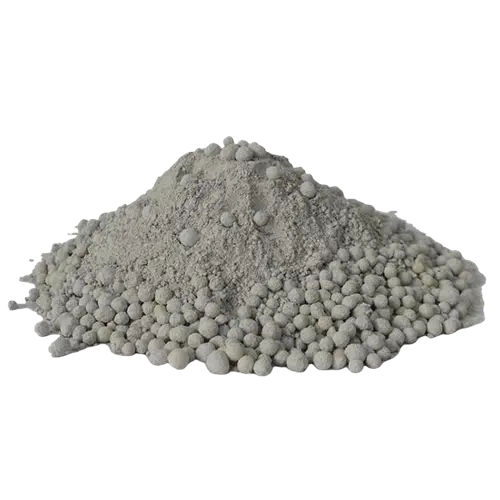

Packing of Chrome Corundum Casting Castables

Plastic bag(25kg), Kraft bag (25 kg), Plastic Ton bag(1 ton);

1 ton on the pallet with plastic film & bundle belts.