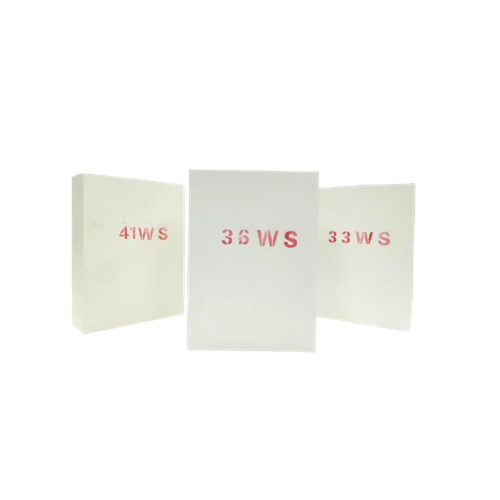

Corundum Mullite Firebrick

Corundum-mullite brick

Corundum-mullite brick refers to a high-alumina refractory product composed of corundum and mullite main crystal phases. Corundum-mullite bricks refer to refractory products made of high-purity or relatively pure raw materials. The presence of low melting point oxide impurities will reduce its high temperature performance. Use pure mullite raw materials synthesized from industrial alumina powder and pure clay, bauxite or silica, especially the alkali metal oxide content should be as low as possible. Products made with mullite pellets as aggregate have good thermal shock resistance, but slightly poor corrosion resistance. Products made with corundum sand as aggregate have good corrosion resistance, but slightly poor thermal shock resistance.

It has good high temperature strength, high temperature creep resistance, thermal shock resistance and corrosion resistance. The physical and chemical properties of a typical corundum-mullite brick are: Al2O3>85%, Fe2O3 0.45%, apparent porosity 19%, normal temperature compressive strength greater than 55MPa, load softening temperature greater than 1700℃, heating line change (1600℃, 3h)-0.1%, thermal shock resistance (1100℃ water cooling) greater than 30 times.

Item | Specification | |||

GMZ-90 | GMZ-85 | GMZ-80 | GMZ-75 | |

Al2O3 % | ≥90 | ≥85 | ≥80 | ≥75 |

Fe2O3 % | ≤0.8 | ≤1.0 | ≤1.0 | ≤1.2 |

Apparent Porosity, % | ≤16 | ≤17 | ≤18 | ≤18 |

Bulk Density, g/cm3 | ≥3.10 | ≥2.85 | ≥2.75 | ≥2.6 |

Cold Crushing Strength, MPa | ≥120 | ≥100 | ≥100 | ≥80 |

0.2MPa Refractoriness Underload℃ | ≥1700 | ≥1680 | ≥1650 | |

Permanent Linear Change, % 1500℃×2h | ±0.1 | ±0.2 | ||