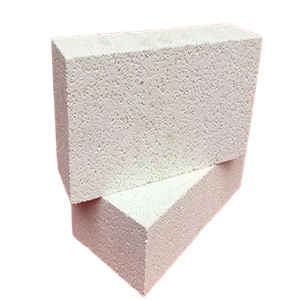

Mullite Insulation Brick

Lightweight mullite insulating bricks

Lightweight mullite insulating bricks, often referred to as lightweight mullite thermal insulation bricks, are a category of thermal insulation bricks capable of withstanding high temperatures exceeding 1790℃. These bricks display a refractory under load temperature range of 1600-1700℃ . They are lauded for their excellent thermal shock resistance, high strength, low high-temperature creep rate, and minimal expansion coefficient. Furthermore, lightweight mullite bricks feature a small thermal coefficient and display excellent resistance to acidic slag erosion. The use of these bricks can significantly reduce the weight of high-temperature furnace bodies, encouraging structural transformation, material savings, energy conservation, and an overall increase in production efficiency.

Item | Specification | |||||||

JM23 | JM25 | JM26 | JM27 | JM28 | JM30 | JM32 | ||

Al2O3 % | ≥40 | ≥50 | ≥55 | ≥60 | ≥65 | ≥70 | ≥75 | |

Fe2O3 % | ≤1.0 | ≤1.0 | ≤0.9 | ≤0.8 | ≤0.7 | ≤0.6 | ≤0.5 | |

Bulk Density, g/cm3 | ≤0.55 | ≤0.80 | ≤0.85 | ≤0.95 | ≤0.95 | ≤1.05 | ≤1.35 | |

Compressive strength, MPa | ≥1.0 | ≥1.5 | ≥2.0 | ≥2.5 | ≥2.5 | ≥3.0 | ≥3.5 | |

Permanent Linear Change% 12h | 1230℃ | 1350℃ | 1400℃ | 1450℃ | 1510℃ | 1620℃ | 1730℃ | |

-1.5~0.5 | ||||||||

Thermal Conductivity, W/(m·K) | 200±25℃ | ≤0.18 | ≤0.26 | ≤0.28 | ≤0.32 | ≤0.35 | ≤0.42 | ≤0.56 |

350±25℃ | ≤0.20 | ≤0.28 | ≤0.30 | ≤0.32 | ≤0.37 | ≤0.44 | ≤0.60 | |

600±25℃ | ≤0.22 | ≤0.30 | ≤0.33 | ≤0.36 | ≤0.39 | ≤0.46 | ≤0.64 | |

Classification Temperature(℃) | ≥1080 | ≥1200 | ≥1250 | ≥1300 | ≥1360 | ≥1470 | ≥1570 | |

Product Advantages:

Low levels of iron and other impurities

High mechanical intensity

High refractoriness, can contact with the flame directly, suitable for various atmosphere

High porosity, low volume density, low thermal conductivity

Good heat insulating performance and energy-efficient

Low creep rare at high temperature,good thermal shock stability

Chemical corrosion resistance

Long service life

Main Applications

Ceramic Roller Kiln Reheating

Reheating Furnace

Blast Furnace

Petrochemical Furnace

General Industrial Furnace etc.