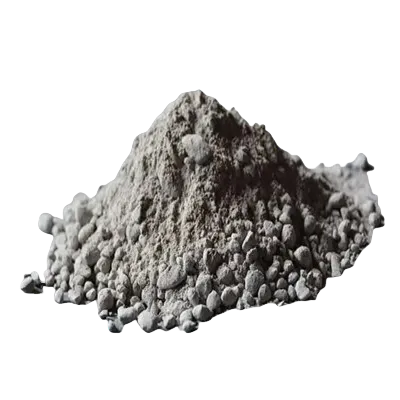

Corundum Refractory Castable

Corundum Refractory Castable

The corundum refractory castable is made of bauxite clinker and corundum with Al2O3 content greater than 90% as aggregates and is produced by combining micro-powder technology and pure calcium aluminate cement. The most important features are high refractoriness and excellent strength.

The corundum castable adopts the method of pouring construction. When customers are using it, they need to add a reasonable proportion of water, stir it with a mixer, and then apply it in a vibrating way. After baking, this product can be put into production use. Of course, customers can also ask us to directly make prefabricated parts according to the use part. The advantage of prefab is that construction is quick and easy, and it can be put into production without baking. This is another important direction for the development of corundum refractory castable.

Parameters of Corundum Refractory Castable for Sale

Item | GYJ80 | GYJ90 | GYJ95 |

(Al2O3) ≥/% | 80 | 90 | 95 |

Bulk Density ≥/ (g/cm³) | 2.7 | 2.8 | 3.2 |

Flexural Strength ≥/MPa | 9 | 10 | 11 |

Compressive Strength ≥/MPa | 60 | 60 | 60 |

Permanent Linear Change ≤/% | ±0.5 | ±0.5 | ±0.5 |

Features

1.High strength.

2.Good volume stability.

3.Excellent anti-erosion performance.

4.High working temperature.

Application

It is mainly used as lining material for boilers, blast furnace, heating furnace, ceramic kiln and other kiln.