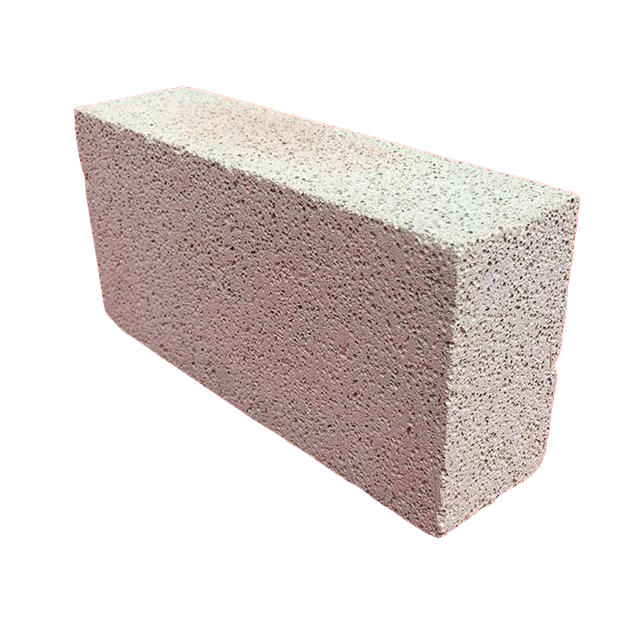

High Alumina Insulation Brick

High Alumina Insulation Brick

High Alumina Insulation Brick are used in building heat insulating walls or heat preserving walls, which is basically for preserving or insulating heat. Light weight high alumina bricks contain more than 48% alumina oxide. This kind of brick does not directly exposed to high temperature inside kilns or furnaces, it only built closely to the kiln wall as insulation. It is a good insulation refractory material, which has a high compressive strength, low thermal conductivity and good insulation quality.

Item | Specification | ||||

LG-0.6 | LG-0.7 | LG-0.8 | LG-1.0 | LG-1.2 | |

Al2O3 % | ≥48 | ||||

Fe2O3 % | ≤2 | ||||

Bulk Density, g/cm3 | 0.6 | 0.7 | 0.8 | 1.0 | 1.2 |

Compressive strength, MPa | ≥1.6 | ≥2.2 | ≥2.5 | ≥3.5 | ≥4.5 |

Permanent Linear Change % | 1350℃×12h ≤-2 | 1400℃×12h ≤-2 | |||

Thermal Conductivity, W/(m·K) 350±25℃ | ≤0.25 | ≤0.30 | ≤0.35 | ≤0.5 | ≤0.55 |

Features

• Low thermal conductivity

• Low heat storage

• High purity, consistent raw materials

• Low iron and alkali flux content gives high refractoriness under load in operating conditions

• High hot compressive strength

• Tight dimensional tolerances

• Large bricks or slabs and special shapes available

• Purpose-designed packaging protects bricks in transit

and facilitates on-site handling

Applications

• Aluminium anode bake furnaces, primary electrolytic cells, holding and melting furnaces and secondary remelt furnaces

• Petrochemical heaters, flues, refining vessels and reactor chambers

• Iron and steel industry, hot blast furnace stoves, hot blast main and bustle pipe, heat treatment and galvanizing furnaces

• Metals, heat treatment and atmosphere furnaces

• Ceramic industry, including kilns for domestic and laboratory use

• Glass industry

• Hot Face and Backup insulation in industrial furnaces