AZS Refractory Brick

AZS Refractory Brick

· “A” of AZS brick is Alumina (Al2O3). Alumina of AZS brick is extremely high and reaches at least 90%. As we all know, higher content of Al2O3 commonly refers to higher refractoriness and density.

· “Z” of AZS brick is Zirconia (ZrO2). Zirconia has better resistance to glass solution erosion. Moreover, it can also reduce the risk of cracking and cracking of bricks due to thermal expansion at high temperatures.

· “S” of AZS brick is Silica (SiO2). Silica forms a dense glass phase in AZS bricks, which can prevent the penetration of glass melt and prevent the melt from eroding the AZS brick.

In addition to the chemical compositions mentioned above, AZS refractory brick also contains Fe2O3, CaO, MgO, Na2O and many other small amounts of chemical elements. Other names about AZS brick are fused cast brick, alumina zirconia silica brick, zirconia corundum brick, fused Zirconia corundum brick and so on. Besides, this kind of brick has better heat resistance features and higher density, so customers often use AZS brick in working environments with higher standards.

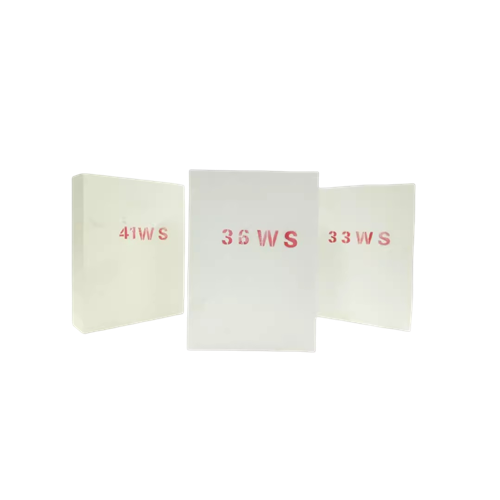

According to different compositions, mainly provides three kinds of AZS refractory brick.You can see from the table below: the more AZS properties and ZrO2 it contains, the better the performance is.

Item | AZS41 | AZS36 | AZS33 |

SiO2, % | 12 | 13 | 15 |

Al2O3, % | standard | standard | standard |

ZrO2, % | 41 | 36.5 | 33.5 |

Bulk Density, g/cm3 | 4.05 | 3.9 | 3.8 |

Apparent Porosity, % | 0.6 | 0.8 | 0.7 |

Initial Precipitation Temperature of Vitreous Phase, ℃ | 1400 | 1400 | 1400 |

Vitreous Phase Exudation, % (1500℃*4h) | 1.5 | 2.3 | 2 |

Anti-molten Glass Erosion Speed Under Static Condition, mm/24h | 1.2 | 1.3 | 1.4 |

Bubble Release Rate, % | 0.6 | 1 | 1.2 |

The Feature:

Fused zirconium corundum brick is a white solid formed by melting and internalization of pure aluminum oxide powder and zirconium sand containing about 65% zirconia and 34% silica in an electric melting furnace and then injected into the model for cooling. Its petrographic structure is composed of eutectoid and glass phase of corundum and zirconium clinite. From the perspective of facies, it is the eutectoid of corundum and zirconium clinite, and glass phase is filled between their crystals.

Fused zirconium corundum brick AZS33# :

The compact microstructure of AZS33# zirconium corundum brick makes the brick have good resistance to glass liquid erosion, and it is not easy to produce stones or other defects in glass kiln. It is a widely used product in glass kiln, mainly suitable for the upper structure of the melting pool, the pool wall brick and paving brick of the working pool, the feed road and so on.

AZS33 is a widely used and widely used product in the AZS series of products, which has superior performance in preventing contamination of glass liquid. It is widely used in the pool wall, the bottom of the pool, the upper structure and the feeding channel of the glass kiln.

Fused zirconium corundum brick AZS36# :

In addition to having the same cocrystallization as AZS33# fused zirconium corundum brick, 36#AZS brick has further enhanced the corrosion resistance of 36# fused zirconium corundum brick due to the increase of more chain-like zirconia crystals and the lower glass phase content, so it is suitable for areas where the glass liquid flow rate is faster or the temperature is higher.

AZS36 is an excellent product in the AZS series of fusible casting products, with high resistance to glass corrosion and low pollution characteristics, and is usually used in key parts such as the pool wall near the hot spot of the melting pool in the glass furnace.

Fused zirconium corundum brick AZS41# :

AZS41# fused zirconium corundum brick in addition to silicon oxide, alumina eutectic, but also contains more uniform distribution

The Application of AZS Bricks

The most important application of AZS bricks is glass furnace.

AZS-33 bricks are mainly used at working tank, fore-hearth, upper structure and crown.

AZS-36 bricks have high corrosion resistance and low pollution to glass liquid, they are mainly used at the parts contacting with glass liquid, such as melting tank wall, clarification tank, working tank and so on.

AZS-41 bricks have the best glass liquid corrosion resistance and the lowest pollution to glass liquid. Their main application parts are: melting tank wall, throat, kiln weir, charging hole corner brick, bubble bricks, electrode bricks and so on.