Silica Ramming Mass

Silica Ramming Mass

Silica Ramming Mass, also known as Acidic Ramming Mass, plays a crucial role in induction furnaces during melting of steel. This substance is used to line induction furnaces. Ramming mass has a very important quality of withstanding and easily absorbing thermal shocks. It also does not develop cracks during frequent power cuts in the operation of the induction furnaces. They are commonly used in metallurgy, building materials, non-ferrous metal smelting, machinery and manufacturing industries. As an intermediate frequency furnace ramming material, Refractory Ramming is applied to melt gray cast iron, nodular cast iron, malleable cast iron, vermicular cast iron, and cast alloy steel; to melt carbon steel, alloy steel, high manganese steel, tool steel, heat resistant steel, stainless steel, molten aluminum and its alloys; to melt red copper, brass, white brass, bronze and its alloys, etc.

Technical Data

Item | GD-95 | GD-96A | GD-96B | GD-97 | GD-90 | |

Chemical composition(%) | SiO2>= | 95 | 96 | 96 | 97 | 90 |

Al2O3<= | 0.7 | 0.6 | 0.6 | 0.5 | 0.4 | |

Fe2O3<= | 0.5 | 0.5 | 0.4 | 0.4 | 0.8 | |

Cold crushing strength(Mpa) | 1300℃×3hAfter firing at | 15 | 15 | 10 | 10 | 25 |

Apparent porosity (%) | 1300℃×3hAfter firing at | 26 | 26 | 25 | 25 | 23 |

Linear changing after burnt(%) | 1300℃×3hAfter firing at | 0~+1.6 | 0~+1.2 | 0~+1.0 | ||

Bulk density (g/cm3) | 1300℃×3hAfter firing at | 2.0 | 2.0 | 2.1 | 2.1 | 2.2 |

Refractoriness(℃) | 1630 | 1650 | 1650 | 1680 | 1710 | |

Max. grain size of aggregate(mm) | 5 | 4.5 | 4.5 | 4.2 | 4.2 | |

Amount for construction(kg/m3) | 2300 | 2300 | 2300 | 2400 | 2400 | |

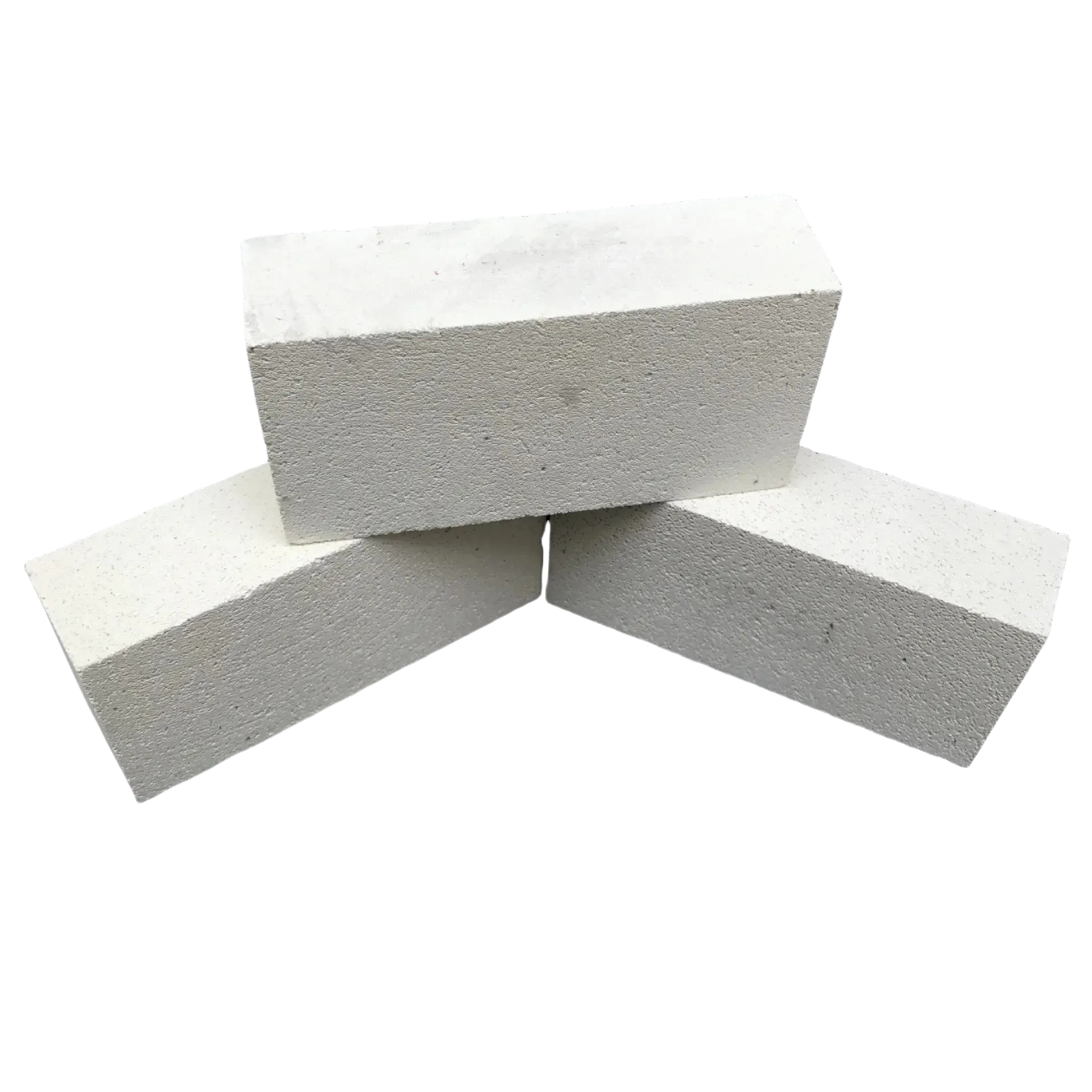

Features

1.Good stability.

2.Good slag resistance.

3.Good fire resistance and resistance to melt erosion.

4.Good chemical stability.

Application

It is mainly used for smelting bronze and red copper in industrial frequency furnace and intermediate frequency furnace.