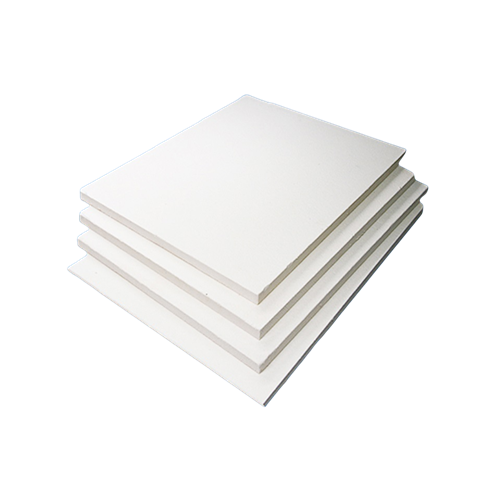

Ceramic Fiber Board

Ceramic Fiber Board

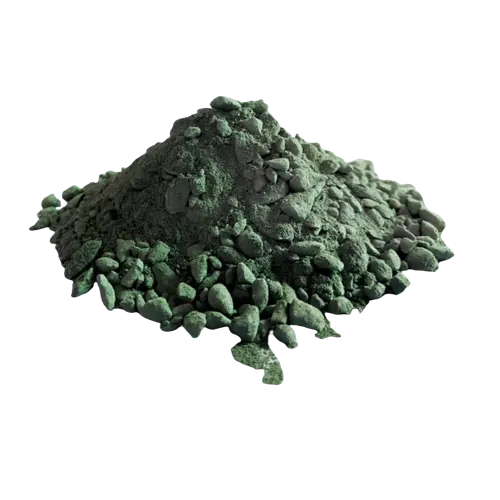

Ceramic fiber board is made of selected coke stones which are melted in an electric furnace at above 2000℃, blown into fibers by machinery, and then uniformly added with binder, oil repellent and water repellent, and then cured by heating.In high temperature applications, ceramic fiber board for is crucial. Customers in high temp industry need this product to realize an excellent insulation effect. This product has a wide range of applications in various industries.It’s important to choose a suitable ceramic fiber board for sale in your business. Please refer to the following table to find suitable ceramic fiber board sheets. Welcome to contact us and help you find proper products.

Technical Ceramic Fiber Board

Item/Grade | Standard Board | High Purity Board | High Alumina Board | Zircon-Alumina Board | |

Classification Temperature/℃ | 1260 | 1260 | 1350 | 1430 | |

Color | White | White | White | White | |

Bulk Density (kg/m³) | 250/300/360 | 250/300/360 | 300/360 | 300/360 | |

Modules of Rupture ≥/MPa | 0.3 | 0.3 | 0.3 | 0.3 | |

Compressive Strength/MPa (10% relative deformation) | 0.15/0.25/0.3 | 0.25/0.3 | 0.25/0.3 | 0.25/0.3 | |

Loss of Ignition ≤/% | 6 | 6 | 6 | 6 | |

Permanent Linear Change ≤/% | 1000℃ x 24h | 1100℃ x 24h | 1200℃ x 24h | 1350℃ x 24h | |

Thermal Conductivity Coefficient /[W/(m·K)] | 400℃ | 0.08 | 0.07 | 0.07 | 0.07 |

600℃ | 0.11 | 0.1 | 0.1 | 0.09 | |

800℃ | 0.14 | 0.14 | 0.13 | 0.13 | |

1000℃ | 0.19 | 0.19 | 0.19 | 0.18 | |

Size | Length, Width Regular Size, Thickness 3-100mm, Customized Size | ||||

Characteristics of aluminum silicate board:

1. High compressive strength and long service life;

2. Low heat capacity and low thermal conductivity;

3. Non-brittle material with good toughness;

4. Accurate size and good flatness;

5. Easy to cut and install, convenient construction;

6. Good wind erosion resistance;

7. Continuous production, uniform fiber distribution and stable performance;

8. Good sound absorption and noise reduction performance.

Application range of aluminum silicate plate:

1. Iron and steel industry: expansion joints, lining insulation, insulation sheets and mold insulation;

2. Nonferrous metal industry: backing insulation materials, tundishes and launder covers, used for casting copper and copper-containing alloys;

3. Ceramic industry: lightweight kiln car structure and kiln hot surface lining, kiln temperature zone separation and fireproof materials;

4. Glass industry: molten pool lining insulation, burner block;

5. Kiln construction: hot surface refractory materials (replacing fiber blankets), heavy refractory linings, expansion joints;

6. Building materials industry: thermal insulation of cement rotary kiln and other equipment.