Refractory Fire Clay Mortar

Refractory Fire Clay Mortar

The refractory fire clay mortar takes high quality and hard fire clay as the main raw material. Customers often use it as the joints among different refractory materials, which is a weak link. Therefore, it’s crucial to choose excellent fireclay mortar for sale. Clay clinker is an important component of clay refractory mortar, which accounts for

about 75% to 80%. Raw clay is a binding agent. It is added to increase the plasticity of clay fire clay and reduce air permeability and water loss rate. The added amount is about 20%-25%.

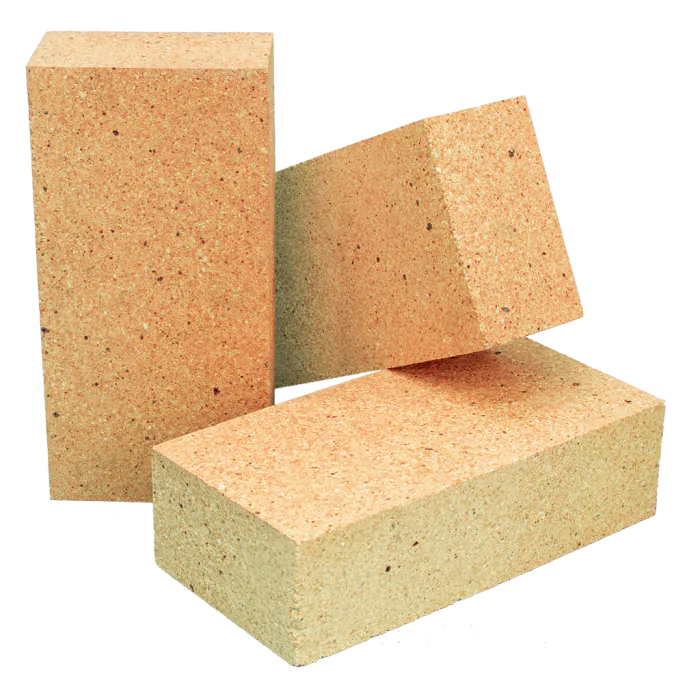

As a joint material, clay refractory mortar can adjust the dimensional deviation of the refractory bricks. This maintains gas regulation and load balance inside the kiln. Masonry can also form a tight whole to resist damage from external forces and the intrusion of chemical gases and molten liquids.

Technical of Refractory Fire Clay Mortar

Item/Grade | NN-30 | NN-38 | NN-42 | NN-45 | NN-45B | |

(Al2O3) ≥/% | 30 | 38 | 42 | 45 | 45 | |

Refractoriness ≥/℃ | 1620 | 1680 | 1700 | 1720 | 1720 | |

Flexural Bonding Strength | 110℃ After Drying | 1.0 | 1.0 | 1.0 | 1.0 | 2.0 |

1200℃x3h After Sintering | 3.0 | 3.0 | 3.0 | 3.0 | 6.0 | |

0.2 MPa Refractoriness Under Load T2.0/℃ | / | / | / | / | 1200 | |

Permanent Linear Change/% (T/℃*12h) | 1200℃x3h After Sintering | -5~1 | ||||

Bonding Time/min | 1~3 | |||||

Features

1. High refractoriness.

2.Fast bonding speed.

3.High cold flexural strength.

4.Granularity standard.

Applications of Refractory Fire Clay Mortar

The clay refractory mortar is mostly used in joints and repairs of blast furnaces, hot blast furnaces, coke ovens, heat exchangers, boilers and other high-temperature equipment in different industries. In addition, customers can also use this product as a part for smelting rare metals in the metallurgical industry.