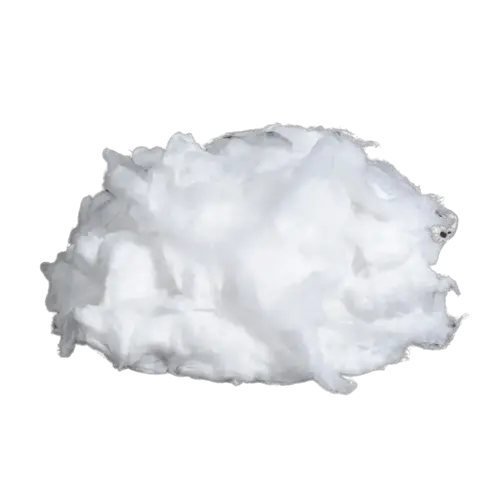

Ceramic Fiber Bulk

Ceramic Fiber Bulk

Ceramic fiber bulk has a wide range of applications for insulation and sealing.Here are different types of ceramic fiber wool for you to choose from. They have different chemical indicators and performance properties. Haoze ceramic fiber cotton is made of high-purity silicon and aluminum raw materials using spinning or blowing processes. In addition, in the vacuum forming process, ceramic bulk fiber is the basis for ceramic fiber blankets, boards, papers and other products. No matter which ceramic fiber wool you choose, they all offer excellent performance.

Item/Grade | Standard Bulk | High Purity Bulk | High Alumina Bulk | Zirconium Bulk | |||

SPUN | BLOWN | CHOPPED | / | / | / | ||

Classification Temperature/ºC | 1260 | 1260 | 1260 | 1260 | 1350 | 1430 | |

Chemical Composition | (Al2O3) ≥/% | 43 | 43 | 43 | 44 | 52 | 35 |

(SiO2) ≥/% | 54 | 54 | 54 | 55 | 47 | 49 | |

(ZrO2) ≥/% | / | / | / | / | / | 15 | |

Color | White | White | White | White | White | White | |

Shot Content ≤/% | 15 | 15 | 12 | 15 | 15 | 12 | |

Fiber Diameter (μm) | 3-5 | 2-4 | 2-4 | 3-5 | 2-4 | 3-5 | |

Product features:

Low heat capacity, low thermal conductivity

Excellent chemical stability

Excellent thermal stability, not easy to powderize at high temperature

Contains no binder and corrosive substances

Excellent sound absorption

Application of Ceramic Fiber Bulk

Used as Insulation Layer

Haoze ceramic fiber bulk is an excellent thermal and insulation material. Using large ceramic fiber wool as the insulation layer of industrial kilns can not only reduce the difficulty of construction, but also greatly improve the insulation effect. The lower thermal conductivity can effectively improve overall energy utilization.

· Thermal insulation materials for thermal reactors and incineration equipment;

· Insulation of wall expansion joints;

· Filling expansion joint;

Used as Lining of Kiln

The furnace and furnace lining are important parts of the industrial furnace. In complex working environments such as high temperatures and chemical erosion, ceramic fiber wool maintains a good structure with its excellent performance. Use this product in industrial kiln linings to resist high temperatures and chemical corrosion.

· Raw materials for fiber coating materials;

· Fiber castable and coating raw materials;

· Wall lining filler for high temperature furnace heating equipment;

Used as Insulation for Other Parts

High-temperature industrial furnaces involve many corners, door gaps, furnace lids and other complex parts, which are also the main areas for heat loss. At this time, the good refractory ceramic fiber wool has a good sealing effect with its flexible shape. Customers can use high-quality ceramic fiber wool to avoid energy loss.

· High temperature furnaces, heating devices, wall lining gap filling materials;

· fire door fillers;

· kiln car filling;

Used for Repair and Maintenance

In a long-term high-temperature working environment, industrial kilns will inevitably suffer from wear, damage and other problems. Ceramic fiber wool is suitable for repairing furnace bodies and can quickly protect the stable operation of the furnace. This product has excellent performance and can extend the service life of the kiln.

· Repair of high-temperature sintering kilns;

· Short-term repair of chemical industry kilns;

· Quick repair of fire-resistant fuel stoves;