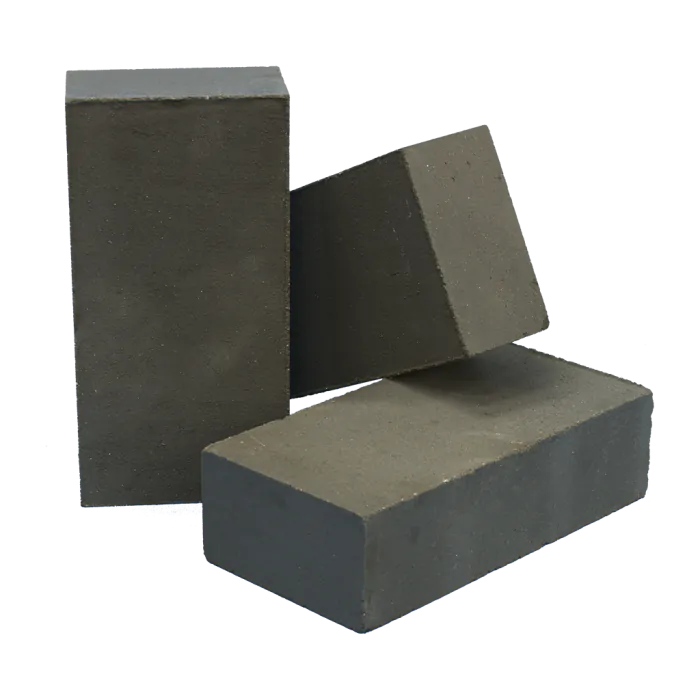

Magnesia Carbon Refractory Brick

Magnesia Carbon Bricks

Magnesia carbon bricks are mainly used for the lining and tapping port of steel making oxidation converter, the hot spot of high-power electric furnace wall, refining furnace lining, the slag line of steel barrel, etc.

Magnesia carbon brick is made of high-purity magnesia powder, carbon materials (including graphite) and tar pitch or resin after batching, hot mixing and molding and being roasted at about 300 ℃ or above 1000 ℃.

Item | Specification | ||||

MT10A | MT12A | MT14A | MT16A | MT18A | |

MgO % | ≥80 | ≥78 | ≥76 | ≥74 | ≥72 |

C % | ≥10 | ≥12 | ≥14 | ≥16 | ≥18 |

Apparent Porosity, % | ≤4 | ≤4 | ≤3.5 | ≤3.5 | ≤3.0 |

Bulk Density, g/cm3 | ≥3.02 | ≥2.97 | ≥2.95 | ≥2.92 | ≥2.89 |

Cold Crushing Strength, MPa | ≥40 | ≥40 | ≥38 | ≥35 | ≥35 |

HMOR, MPa 1400℃×0.5h | ≥6 | ≥6 | ≥10 | ≥8 | ≥10 |

Features

As a composite refractory, magnesia carbon brick effectively makes use of the strong slag erosion resistance of magnesia and the high thermal conductivity and low expansion of carbon, and compensates for the poor spalling resistance of magnesia. It has the characteristics of slag erosion resistance, slag permeability, thermal shock stability and thermal conductivity.